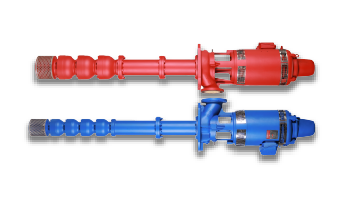

Oil & Gas Pumps

In the oil, gas and petrochemical industry many different types of pumps are used in machines and installations. There is no such thing as the one and only pump in this branch.

Introduce

In the oil, gas and petrochemical industry many different types of pumps are used in machines and installations. There is no such thing as the one and only pump in this branch. The choice of pump depends on the final application, which ranges from the exploration, delivery and recirculation as well as further transport for loading/unloading of tanks, tanker trucks and ships.

The right pump for oil and gas delivery

In the different parts of the world in which oil and gas is extracted, all types of different requirements must be observed, e.g. due to the sulfur content. In exploration, for example, it is often required to safely transport multi-phase mixtures (mixtures consisting of gas and fluids). In this case, centrifugal and screw spindle pumps are generally the right solution, because these pumps can safely handle viscous media or media contaminate with solids which often occur.

Pumps for difficult delivery conditions

In the most recent past, fracking and the processing of oil sands have brought about new processes that frequently impose the highest demands on the head. A typical solution consists of piston or plunger pumps. Further processing takes place in refineries, where all types of different fuel and source materials for the chemical industry are produced. The pumps used here have to meet the highest safety requirements. For this reason, centrifugal pumps or even vacuum pumps / liquid ring vacuum pumps are used. The tendency towards ever more stringent requirements on availability, safety and lowest emissions means that next to expensive shaft sealing systems, an increasing number of seal-less, hermetic drives – such as the magnetic coupling or the canned motor pump – are used, which are suitable for explosive atmospheres 1 & 2. These pumps often excel with a long mean time between failures (MTBF) and long maintenance intervals.

For help with pump application, please contact us to get the best support.

Your Local Contact

Versar Industrial Solutions Pte.

Email: enquiries@versar.com.sg

Contact UsPumping Solutions

practical applications.

Versar pumps convey kerosene, diesel and other media at discharge pressures of 10-40 bar and temperatures up to 400 degrees Celsius. The API 610 describes the typical demands placed on centrifugal pumps. Double mechanical seals to API 682 are used almost exclusively, or canned solutions to API 685, which are increasingly being used.

SPECIAL ENVIRONMENTAL

Where ambient noise levels are of concern, VERSAR can supply Soundproofing to reduce equipment noise to lowest levels. Enclosures can be designed to cover all or part of an industrial oil pump and gas pump package dependent upon the specific requirements of the installation/site. Enclosures and complete modules can also be supplied EI60 or EI120 fire rated. Water mist systems can also be included.

For projects where environmental conditions or location dictate that minimal on-site installation works are preferred, VERSAR Pumps are able to offer fully packaged skids or pump houses incorporating multiple pump sets.

OFFSHORE SERVICE

VERSAR Pumps Field Service Engineers travel the world in the support of VERSAR Pumps engineered products. Suitably qualified in all Health & Safety aspects with extensive experience working on both land based projects and offshore located oil & gas installations. Be it installing, commissioning, testing or remedial tasks, VERSAR Pumps engineers can be mobilized within a few hours.

.png)